The company is replacing its 17-year-old 18m hygiene stack and the 42m den stack with a 45m combined air discharge stack tomorrow.

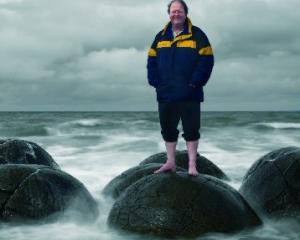

Ravensdown Works manager Craig Hendry said combining the den and hygiene stacks was a requirement of the air discharge permit granted to Ravensdown by the Otago Regional Council in September 2005.

Mr Hendry said dispersion modelling carried out for the air discharge permit application indicated air quality was expected to improve, particularly near the works.

The main contaminant discharged from the fertiliser manufacturing process was fluoride and Ravensdown operated two scrubbing systems to reduce its levels.

"The purpose of these scrubbers is to remove almost all the fluoride from the steam discharged to air.

"Once the combined stack is installed, Ravensdown will continue its fluoride monitoring programme in the Ravensbourne environment to ensure that discharges are not having an adverse effect."

Ravensdown would continue to provide regular monitoring reports to the Ravensbourne Community Liaison Group and the Otago Regional Council, he said.

While the scrubbing systems were being replaced, production of fertiliser had to be halted.

Mr Hendry said demand for fertiliser in the region was ahead of last year and the disruption was being kept to a minimum.

The plant had been shut down since Monday for the installation, and fertiliser production was expected to resume on Monday.