Up to 30 calves are arriving daily on the Taieri dairy farm of Duncan and Anne-Marie Wells.

Calving of the couple’s 650 cows started in late July and will finish in early October.

It is the biggest event for the cows each year.

‘‘There are opportunities for it to go right and opportunities for it to go wrong and we want to provide the best care we can for every individual cow,’’ Mr Wells said.

Tips for getting through included ‘‘pacing yourself and having a break during the day to refresh and carry on’’.

If anyone was becoming overwhelmed during calving they should call a vet or neighbouring farmer to create a plan to get through.

‘‘You’re not always going to get it all 100% right,’’ he said.

When it was less hectic on the farm, the Wells family hosts other dairy farmers and industry reps at DairyNZ field days.

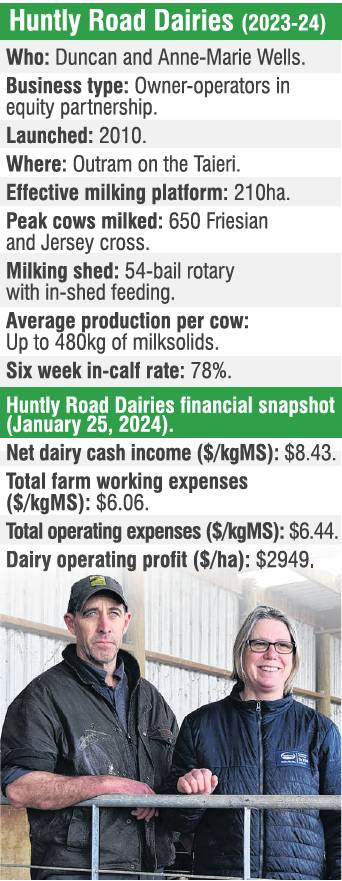

A field day in May highlighted a case study exploring the financial performance of their business, Huntly Road Dairies.

If he had been asked to be involved in the financial case study he would have declined.

Mrs Wells said she was a ‘‘sucker for saying yes’’, although she did worry hosting field days and sharing their finances could be perceived as ‘‘showing off’’.

The motivation for taking part in the case study was to show the value in continually tracking spending to maximise profit.

Often farmers shared information, such as milksolids per cow and in-calf rate, without providing any other information on how much it cost to produce those outcomes, she said.

‘‘Nobody talks about money, they all talk about milksolids’’.

Some farmers could feel deflated when they only compared production results, she said.

When they were able to benchmark against a list of performance indicators they realised they were doing all right.

A benefit of field days was they could see other farmers were in the same boat.

The goal of Huntly Road Dairies was to be profitable, which requires doing everything right in every part of the business, she said.

‘‘If you have good animal health, in-calf rate, milksolids and shed hygiene, you’ll make money.’’

An important part of the farm business was trusting the advice from rural service providers such as artificial breeding technicians, fertiliser and seed representatives and vets, Mrs Wells said.

‘‘We use people as experts in their field and Duncan is an expert in the farming field and that fits well for us.’’

Their bank manager and accountant were key parts of their business, she said.

Mr Wells said the compact medium-sized Friesian and Jersey cross cows matched the infrastructure on the farm.

Between 60% and 80% of the herd were wintered off farm for up to 10 weeks.

The business had decided against building a winter barn on the farm for now because it would require buying in a high quality supplementary feed and breeding a bigger cow which was interested in eating from feed bins, Mr Wells said.

‘‘No doubt we would get heaps more milk per cow but I don’t think I want to go down that route.’’

However, when adverse weather hit he did ponder if his decision against building a barn was the right one.

‘‘I question it every time.’’

‘‘People are pretty quick to tell me what production their cows do and our cows don’t.’’

Another goal on the farm was maintaining milk production while slightly reducing cow numbers by breeding a better performing cow and lifting the volume and quality of the feed grown on farm.

The farm business had invested in Smaxtec smart boluses to monitor the health of their herd.

Boluses were fed to the cows, lie in their stomachs and provide cow health information.

The information would help aid decisions to making subtle changes to their system to improve the health and performance of the herd.

‘‘Hopefully it will give us a nudge towards doing things slightly different.’’

Neither of them were born or raised in the district.

Mr Wells was born and raised on a dairy and kumara farm in Dargaville, Northland and moved south about 20 years ago.

His career progression in Otago included working on dairy farms in Oamaru and Maniototo.

He was a lower order sharemilker in Mosgiel and bought the herd from the owner and stayed on as a 50:50 sharemilker.

The couple met on a trekking holiday in Ladakh in the Kashmir region in 2007.

At the time, he was sharemilking and Mrs Wells was a software engineer from Bath, England.

The pair moved to Mosgiel and she took on the office work of the sharemilking business.

‘‘You have a real passion for office work,’’ Mr Wells said.

Mrs Wells agreed her attention to detail in the office was her major strength on farm.

She considered herself lucky to be able to do the office work and raise their children Aidan, 15, Liam, 13 and Hannah, 12.

Mr Wells said Otago had been a good place to progress in the dairy industry and the province had a lot to offer.

Farm ownership was a goal but ‘‘by no means certain’’.

Challenges to farm ownership were being able to service a debt when interest rates and input costs were high and potential for unanticipated challenge such as a drop in the milk price.

‘‘Our returns are pretty tight.’’

A new input cost was the $4000 to obtain a 10-year consent for their effluent system in March last year to meet new rules for storing and applying animal effluent.

The system was installed when a new milking shed was built on the farm in 2011.

To build an 150,000-litre impact pond and stone-trap cost $80,000 and a 1 millionlitre megapond cost $180,000, including site work the following season.

The new shed features a feeding system providing crushed barley to the cows.

He chooses to feed crushed barley because it supports Canterbury croppers rather than an imported feed, such as palm kernel.

‘‘Our cows would probably perform better if we fed them palm kernel but we choose not to.’’

The public and the government needed to be patient with farmers on imposing environmental regulations.

‘‘Farmers don’t like being pushed and being told to hurry up and do something.’’

Farmers knew change was required and they would get there by continuing to deliver on environmental improvements.

‘‘We are not going to take the elevator, we are going to take the stairs and we’ll get there but one step at a time and everyone will be fitter for it when we get there.’’

- Nobody talks about money, they all talk about milksolids