Clutha contract milker Jorg Sahin is searching for the best investment to make his business more efficient.

Options being explored include installing automatic cup removers in the milking shed or investing in cow wearables, such as ear sensors or smart collars.

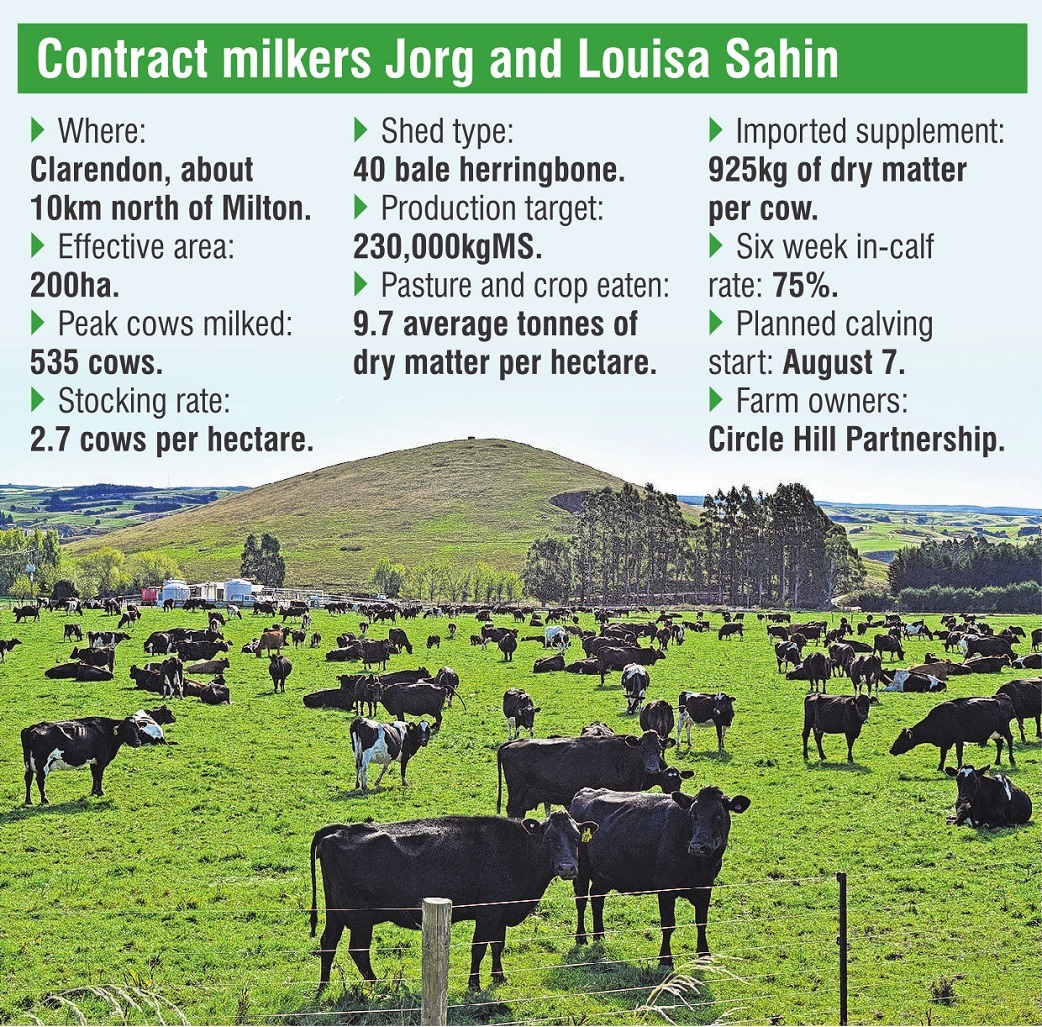

To aid the decision, he asked farmers for their thoughts at a DairyNZ field day on the 200ha farm where he contract milks. The farm borders State Highway 1, near the the Ewing Phosphate Co building in Clarendon, north of Milton.

He and his wife Louisa were in their second season contract milking more than 500 KiwiCross cows.

The farm is owned by Circle Hill Partnership Ltd and most of the shareholders live in the North Island.

"We have great owners," Mr Sahin said.

One of his business goals was to feed the herd to its potential and produce 500kg of milksolids per cow.

Now each cow produces about 430kg of milksolids on average.

"That is my biggest pet hate."

Ideally, the milking shed would have automatic cup removers.

He ran his cows in one herd but he once had it split in two mobs

because they were unable to fit in the yard at one time, which meant when they were in one mob they wait a long time to be milked.

He would prefer the cows spent that time grazing so they could produce more milk.

When the herd was split, the cows got more time in the paddock, he said.

The splitting of the herd in past seasons had increased milk production but it put pressure on the staff member milking the first herd when the other staff member brought in the second mob.

"It is not ideal," Mr Sahin said.

A single staff member being able to milk the cows on their own was a "game changer", Mr Frost said.

"Why would you want to have two people milking cows when you can have one."

Automatic cup removers would improve farm efficiency more than cow wearables, Mr Frost said.

The investment by the farm owners to install automatic cup removers was worth it, he said.

"It is all about productivity, isn’t it?"

Farm owners should invest in any technology which made it easier to attract and retain good staff, Mr Frost said.

Mr Sahin wondered if he had cup removers, if it would be too much to ask one staff member to milk the entire herd themselves in a herringbone shed.

A lack of farm workers entering the dairy industry made him nervous.

"I still use them. The best investment I’ve ever made in my time of farming is cup removers — by a country mile. "

They would make a farm more efficient and make the farmer more money long term than investing in cow wearables he said.

The cup removers benefit the farm owners because it helps retain good staff, which were harder to recruit.

"People are not as interested in milking cows as they once were."

He encouraged the Sahins to explain to the owners about the challenges of recruiting good staff and the possible consequences of having mediocre staff such as lower milk production and in-calf rate.

A compelling argument would help a farm owner understand why a contract milker wants them to invest in a technology, Mr Frost said.

DairyNZ extension partner Gareth Baynham, of Invercargill, said if a dairy farmer was short on staff, they could find themselves "being dragged into doing $25 an hour jobs".

"That is taking your eye off those $1000 an hour jobs like getting that pasture management bang on."