Southern dairy farm owner Ivan Lines is continually seeking better ways to increase productivity and reduce environmental impacts on his properties.

Mr Lines is one of the dozen families in a syndicate which own six dairy farms in Northern Southland and West Otago.

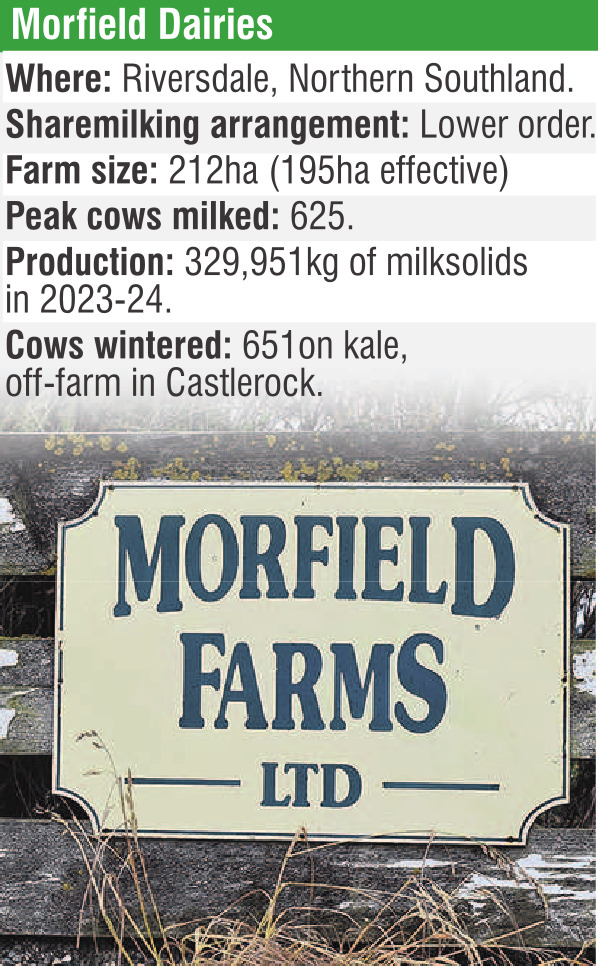

Nine of those families, including Mr Lines’, were invested in Morfield Dairies in Riversdale.

More than 600 cows get milked on Morfield Dairies by lower order sharemilker Glen Cunningham and his two full-time staff.

Pivot irrigators had been installed since the syndicate bought the farm in 2008.

The pivots replaced Roto-rainer irrigation, which once resulted in the loss of 104kg of nitrogen per hectare.

Pivots resulted in the loss of 44kg of nitrogen per hectare, Mr Lines said.

"We basically halved our nitrogen-loss by simply investing $1 million in pivots."

On Morfield Dairies, 185kg of nitrogen was applied per hectare last season.

"What do we have to do to make that lower and make money at the same time?"

To help answer that question, Morfield Dairies was taking part in a DairyNZ project investigating the systems of 10 dairy farms in the Waimea catchment.

The project aims to identify on-farm efficiencies to further reduce nitrogen losses, while maintaining profitability and not increasing greenhouse gas emissions.

1. Reducing the milking herd by about 11% and using the same amount of feed to increase milk production of the remaining herd.

2. Keeping the current stocking rate and building a winter barn, harvesting silage from the current winter crop to feed out in it.

3. Building a wintering barn and reducing the milking herd so the existing milking platform could provide sufficient feed for wintering and lactation.

Mr Lines said when considering the first option, the farm owners wanted to make sure their sharemilker would not be losing income as a result.

Any change to herd size should be made in smaller steps rather than one massive hit "because if you get it wrong it is going to have a major impact on profitability".

If a herd size was being reduced, then the remaining cows need to be fed to their potential to increase milk production per cow, Mr Lines said.

Cow numbers had fallen on Morfield Dairies.

The 651 cows wintered this season was 19 fewer than the prior season.

One of his objectives was to reduce the number of the syndicate’s cows wintering on crop.

Eight years ago, all of the cows om the syndicate’s farms were wintered on crop.

Now, half of the cows were wintered on crop and the rest were wintered on grass or on infrastructure, such as freestall barns.

A freestall barn for 580 cows was built on another syndicate farm last year at the cost of about $4500 per cow.

A cow which required 14kg of maintenance feed a day in a paddock only needs 11kg in a barn.

"If we can reduce our nutrient-loss and maintain profit then it is a win-win."

A negative of installing a barn was it increasing greenhouse emissions on a farm, because it required pouring concrete and the use of machinery to feed the cows.

"There is a trade-off, because you are reducing your nutrient loss but your greenhouse gas emissions are going up. It is hard to get the perfect solution."

If a farm owner was considering building a barn, they needed to have a reliable supply of feed available to reduce their risk.

"You wouldn’t want to expose yourself to the market, because silage is hard enough to come by in this area in the best of times."

Consequently, for a barn to be built on Morfield Dairies, a guaranteed feed supply was needed, which could require adding a lease block or run-off to the farm system.

However, the project had shown if Morfield Dairies became a self-contained system it would negatively impact profitability "so that’s not an option".

The business had three key objectives, Mr Lines said.

At the top of the list was returning a dividend to shareholders.

"People have invested in these businesses to make money and we’ll make no apologies that our objective is to provide a really good return on investment for those shareholders."

Retaining staff was the second objective.

All of the farms had sharemilkers and in the past 14 years, one had moved on and one had retired.

The third objective was to produce milk efficiently.

Production on Morfield Dairies last season equated to 1.07kg of milksolids per kg of cow liveweight.

A future goal was for the cows to produce more than 1.2kgMS/kg liveweight.

"In my opinion, that is the future of the industry."

An in-shed feeding system was installed in the herringbone shed on Morfield Dairies about four years ago.

The farm owners paid for all the feed costs on Morfield Dairies, and their sharemilker got 22.5% of the income.

Consequently, the owners had to be aware of how much feed was costing and impacting their profit margin.

The cows at Morfield Dairies were given 20% more meal in-shed during spring this season compared with spring last season, due to inclement weather.

The amount of silage given to the cows had been reduced and replaced by meal.

"Silage is maintenance feed. You don’t get big production out of silage."

Most farmers wanted to do the right thing and further reduce nitrogen-losses on farm, Mr Lines said.

"They just need to have the confidence they are doing the right thing."