The site is expected to export about 20,000 tonnes of cream cheese to China this season, and 1500t to Southeast Asia. That’s about 7.9t of cream cheese for every person in the nearby small township of Darfield which has a population of about 2700.

The dairy giant increased its cream cheese output to meet demand before this month’s Lunar New Year.

This is mostly being driven by an expanding middle class and growing appetite for cream cheese in a wide range of applications from bakery to beverage making.

The fusion of traditional Chinese pastries and dairy ingredients such as cream cheese is increasingly popular around Lunar New Year when families gather to celebrate.

Darfield has managed to increase its yearly production by 2100t as a result of being more efficient and without extra spending.

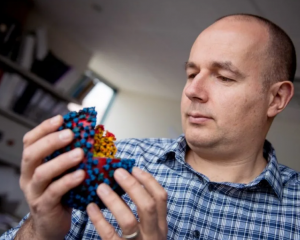

Plant manager for cream cheese Matt Smith said they were definitely back to pre-Covid-19 sales levels and were likely exceeding them now.

"Where we see the big areas of demand are tea macchiatos, so beverages with that cream cheese and Anchor whipping cream on top and the big growth we’ve seen recently is the fusion of that traditional pastries like moon cakes where we can start adding cream cheese and dairy. So we are seeing big growth there and good stable demand now for cheese lollipops."

Mr Smith said they were pleased to make more cream cheese without adding costs.

Four shifts of teams produced the cream cheese with no further staff added to run the extra processing.

"That’s a real exciting one for us, seeing the demand coming through and having a real focus on how we run the plant and what we can do to improve. They’re all comparatively small tweaks but, with the focus and a few adjustments, we’ve managed to get another just over 2000t a year of product which is great news for farmers — no money and extra output."

Key changes made were picking up the speed of processing and being "faster and smarter" with the daily cleaning turnaround time.

Site operations manager Blake Aston said Fonterra was connected to customers in its markets, and this was an example of the team making process changes to meet increased demand.

Mr Smith said Lunar New Year was the peak of cream cheese production, but yearly demand was growing as well.

"We are still seeing China increasing dairy production and the growing middle class, so there’s a good upward trend year-on-year and a spike each time in the New Year. We are definitely seeing a growth and it took a rattle through Covid-19 being food service focused, but the underlying growth is there for us, definitely."

They are similar-sized plants but Darfield is making more this year.

The bulk of the cream cheese goes into food service business under the Anchor Food Professionals brand and also into ingredients for the likes of processed cheese and cheese lollipops for outlets such as bakeries, catering, restaurants and tea shops.

Mr Smith said Fonterra was working in markets to design products for cream cheese customers.

"Depending what it’s going into, they might suggest they use a softer cream cheese or a firmer cream cheese or one with a different fat content or different flavour and our plant being so new has the technology to adapt to make whatever suits the customer."

Darfield was opened in 2012 with the cream cheese operation starting in 2018.

The site is the collection point for milk from more than 1100 farms ranging from the Mackenzie Country to the top of the South Island.

About 7.5 million litres is processed a day during the peak of the season with about 90% going into milk powder and the rest into cream cheese.

Fresh milk and cream went into cream cheese processing with about 9t to 10t made daily.

"What really sets our cream cheese apart is it’s a fermented cream cheese, so we add starting cultures fermented overnight to get this really great cultured flavour into the curd.

"It’s a really traditional cream cheese process and that gives a really good flavour and gives us that flexibility to make it how we want to."

He said seeing cream cheese being made in Darfield and ending up on plates in big cities such as Beijing, Shanghai, or Hanoi was a source of pride for the team.

"With 300 employees, we’re a big part of the local economy, providing jobs for the region and helping New Zealand succeed on the world stage."

Mr Smith said the co-op’s increase this month in the farmgate milk price forecast by 30c to a new midpoint of $7.80 a kilogram of milksolids — up from $7.50/kg — would help farmer suppliers.