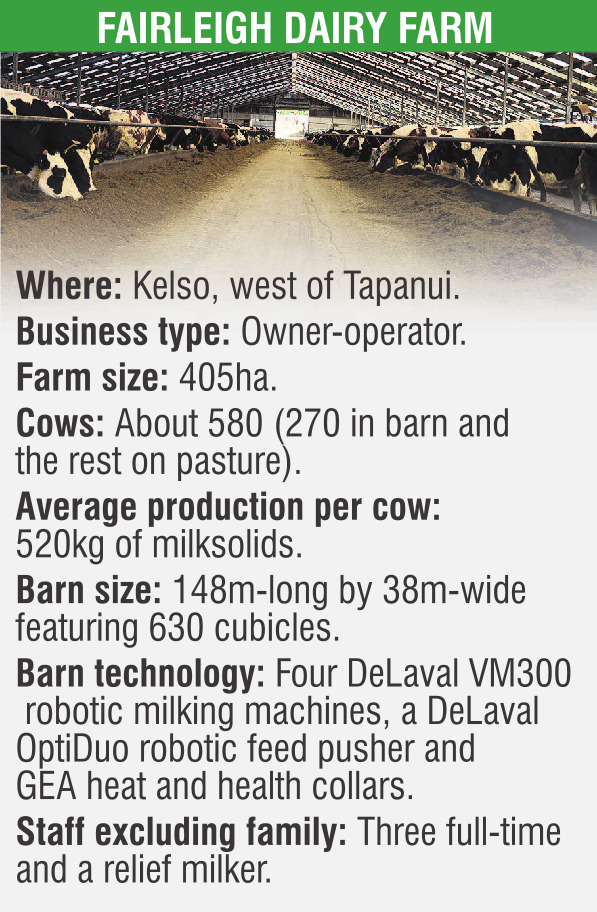

Bruce Eade was at school when his parents Ken and Nancy Eade converted their nearly 405ha West Otago property Fairleigh to a dairy farm in 1995.

A hay shed and covered yards were the only farm buildings on the gentle rolling former sheep and beef and dairy grazing property.

The construction of a new 30-aside herringbone shed was ongoing when the cows began calving and required milking to launch production of their first season.

"We were milking 80 heifers in that hay shed on a two-cow plant with an extension cord from the meter box," Mr Eade said.

Fast-forward three decades and nearly half of the herd are milked by robots.

"We have gone from one extreme to the other in 30 years," he said.

Now about 580 cows are milked, about 70% Holstein Friesian, 25% Ayrshire and 5% Jersey.

A split-calving model was launched about 12 years ago.

A freestall winter barn was built in 2012 and Mr Eade described that as a game-changer.

Heavy cows could pug soil in a wet winter so the barn was a way to get the herd off pasture.

"The catalyst was a September and I was feeding out in a paddock and it was snowing so hard I had to stop and wait for it to finish because I couldn’t find my way back to the gate in my tractor. We thought there must be a better way."

The herringbone shed was extended to a 40-aside, six years after the farm conversion but more milking infrastructure was needed.

In the peak of season, more than 300 cows are milked in the herringbone shed.

"That’s the first time in 14 years it hasn’t been operating twice-a-day, every day of the year."

They had considered constructing a new 60-bale rotary shed as the herd size increased but it would have needed to be built on the existing herringbone site so logistics would have been challenging.

Another consideration is staff being harder to find to work on dairy farms.

As they already had the winter barn "it just made sense" to install robotic milking machines in it about 18 months ago.

The project cost about $1.2million including earthworks, a barn extension and four DeLaval VM300 robotic milking machines, a DeLaval OptiDuo robotic feed pusher and GEA heat and health collars for cows.

On average, the cows in the barn are milked by the robots two and a-half times a day.

"The top cows are milking seven times in two days on their own free will."

Feed provided for cows in the barn and milking machines includes grass silage, wheat silage, maize and dried distillers grain.

Each day cows get 3kg of a dairy pellet supplied by Sgt Dan Stockfoods.

The cows on pasture and milked in the herringbone shed are put in the barn in winter and are given the same feed as the herd milked by robots.

Wheat for silage, about 25ha, has been grown on Fairleigh for the past 15 years.

They are in their second season growing maize, about 30ha, producing nearly 20 ton of dry matter per hectare.

"We do our own cultivation, our own slurry spreading and everything. We pretty much do it all. We rear our young stock, we keep the Friesian bull beef calves — we are farming the way it used to be."

Most bull calves are reared and wintered on kale and baleage and sold as stores in spring.

The original herd on Fairleigh was all Ayrshire but when they wanted to increase herd numbers to 300 in the first year, they could not find any to buy.

Their stud Fairleigh was launched after Mr Eade’s father bought his first Ayrshire calf in 1965 and Holstein Friesians were introduced from 1995.

"As we’ve been in Ayrshires so long they’ll always have a place on the farm."

The breeding programme targets producing a medium-sized cow with a good udder, feet and legs, able to produce plenty of milk.

Data from the robotic milking machines shows the cows in the barn were closer to reaching their genetic potential for production due to reasons including the removal of any negative impacts of weather, grass quality and reducing the distance the cows need to walk for milking.

"We can see our farming style had been holding them back."

The Eade family had not beenshowing dairy cattle in recent years due to being busy with farm projects but "the urge still burns deep" and they would return to it, Mr Eade said.

"We love the showing and the camaraderie and being in the public eye but we do it right or we don’t it at all,"

He hopes at least one of theirchildren will want to continue the family farm business.

"I won’t see 100 years on our farm but maybe one of my kids or grandkids will, that’s the goal."